The Global Landscape of Vacuum Filtration Standards

Vacuum cleaners around the world are subject to different filtration expectations and standards, especially when it comes to HEPA (High-Efficiency Particulate Air) filters. In some regions, regulations or rating systems encourage manufacturers to use high-grade filters and sealed designs, while elsewhere it’s driven more by consumer demand than law. In this article we will compare how key regions approach vacuum filtration.

United States

There is no federal law requiring HEPA filters in household vacuums, but the term “True HEPA” is a common industry benchmark. The U.S. Department of Energy originally defined HEPA filtration as removing 99.97% of particles 0.3 microns in diameter [EPA.GOV]. Many American vacuums advertise “True HEPA” filters meeting this standard. However, lesser terms like “HEPA-type” or “HEPA-like” can be used in marketing even if the filter doesn’t meet the full 99.97% efficiency – these terms have no official definition and often indicate lower performance

[EN.WIKIPEDIA.ORG].

For industrial or hazardous-material use, U.S. regulations do step in. For example, EPA rules for lead paint remediation mandate using a vacuum with a HEPA filter that exhausts all air through that filter with no leaks [EPA.GOV]. (In practice, this essentially requires a sealed system design, as discussed later.)

Certification programs also fill the gap – the Asthma and Allergy Foundation of America (AAFA) certifies certain vacuums for allergy-friendliness, requiring that they effectively trap allergens and don’t release particles back into the air [ASTHMAANDALLERGYFRIENDLY.COM].

European Union

Europe has historically taken a more regulatory approach. The EU’s dust re-emission classification was a part of its vacuum cleaner energy label in the 2010s. Vacuums were graded “A” (best) through “G” based on what percentage of dust they emit from their exhaust. To achieve a top “Class A” filtration rating, a vacuum could re-emit at most 0.02% of the dust it picked up (meaning 99.98% retention) [STORAGE.TOPTEN.EU] – effectively HEPA-level performance. This pushed European manufacturers toward sealed systems and true HEPA filters to meet the standard. An EU consumer guide strongly recommended Class A vacuums for households with allergy sufferers, underscoring the importance of containing fine dust [ENERGY.EC.EUROPA.EU].

It’s worth noting that the EU labeling regulation was annulled in 2018 after legal challenges (spearheaded by Dyson) regarding how vacuums were tested [THE-INDEPENDENT.COM]. As a result, the mandatory label (including dust re-emission class) is no longer in effect. Even so, many vacuums sold in Europe continue to feature HEPA or high-efficiency filters, and manufacturers often comply with standards like EN 1822 (the European norm defining HEPA filter classes) to advertise filtration levels. European models may specify filters as “H13” or “H14” (per EN 1822 classification) to indicate their efficiency (more on these classes in the next section).

Japan and Other Regions

Japan does not have a specific household vacuum filtration law equivalent to the former EU label, but Japanese consumers are very quality-conscious. Major Japanese brands incorporate advanced filtration by default – many use HEPA filters and some even tout ULPA (Ultra Low Penetration Air) filters in high-end models. For instance, certain Hitachi vacuum units designed for ultra-clean applications come with ULPA filters capturing 99.9995% of 0.15 µm particles [ORANGEBOOK-DIGEST.COM].

In general, Japanese vacuum standards align with international norms: HEPA filters are defined similarly (around 99.97% @ 0.3 µm), and product literature often references HEPA class (e.g. “HEPA H13”) or foreign certifications (some Japanese models carry European allergy-friendly certifications like ECARF). Elsewhere in Asia and worldwide, HEPA filtration in vacuums has become a de facto quality standard even absent government mandates. Countries like China often adopt or recognize the same IEC/ISO test standards used in Europe.

In summary, the concept of HEPA filtration is global – what differs is whether it’s enforced by regulations (as the EU did for a time) or left to market forces and third-party certifications.

HEPA Filters 101: Microns, Efficiency, and Classes

To understand vacuum filtration, we need to understand what a HEPA filter is and why “0.3 microns” is the magic number. Microns (micrometers) are a unit to measure particle size – one micron is one-millionth of a meter. The particles that vacuum filters target – dust, pollen, pet dander, mold spores – range from a few microns up to tens of microns in size. (For perspective, a human hair is about 50–75 microns wide, which is over 150 times larger than a 0.3 µm particle [VACUUMWARS.COM].) A HEPA filter’s job is to trap these tiny particles so they don’t blow back into your room’s air.

Why 0.3 µm?

It turns out that particles around 0.3 µm in diameter are the hardest for filters to capture – this size is called the MPPS (Most Penetrating Particle Size). Particles larger than 0.3 µm are usually caught more easily (they either get stuck in the fibers or crash into them), and particles much smaller than 0.3 µm tend to move erratically (Brownian motion) and get snagged by filter fibers via diffusion. So if a filter can reliably capture 99.97% of 0.3 µm particles, it will actually do even better on both larger and smaller particles [EPA.GOV]. That 99.97%@0.3µm benchmark is exactly how HEPA is defined in U.S. standards [EPA.GOV]. In other words, a “True HEPA” filter will remove at least 99.97% of the worst-case particle size from the air that passes through it.

HEPA filter construction

These filters are made from a mat of densely packed fibers (often fiberglass or polypropylene). Airflow through a HEPA filter is forced through a maze of tiny passages. As air weaves through, particles collide with fibers and stick. The filter is “mechanical” – it doesn’t neutralize particles, it simply traps them in the fibers. Over time the fibers load up with dust, which is why most HEPA filters need periodic replacing or cleaning to maintain performance. If the filter is clogged and the vacuum’s seals aren’t tight, air may find paths around the filter – effectively bypassing it. (We’ll cover sealed systems in the next section.)

True HEPA vs. “HEPA-Type” – Not All Filters Are Equal

Because “HEPA” has become a buzzword for high quality, some products advertise “HEPA-type” or “99% HEPA” filters. It’s important to know these do not meet official HEPA standards. A true HEPA filter is rigorously tested to meet that 99.97% @ 0.3 µm threshold (as set by the U.S. DOE) [HEPACART.COM]. In Europe, the analogous requirement is 99.95% minimum at the MPPS, per standards like EN 1822 and ISO 29463 [EN.WIKIPEDIA.ORG]. Filters that fall short might still be decent filters, but they could be, say, 90% or 95% efficient – not enough to trap the finest allergens. Marketing terms like “HEPA-like” or “HEPA-style” are not backed by standardized testing and are largely used to approximate performance without guaranteeing it [EN.WIKIPEDIA.ORG].

In short, either a filter is certified to HEPA level or it isn’t – there’s no official “almost HEPA” category. Consumers should look for explicit terms like True HEPA or filters rated H13/H14 (explained below) rather than vague phrases. In fact, U.S. EPA guidance for contractors warns that simply retrofitting a HEPA-like filter onto a vacuum doesn’t ensure performance if the vacuum isn’t designed for it (air may bypass the filter in an unsealed machine) [EPA.GOV]. The same principle applies for home vacuums.

HEPA Grades and Classes (H13, H14, etc.)

You may have noticed some vacuum specs (especially in Europe or on high-end machines) list filters by classes like H13 or H14. These refer to specific tiers of HEPA efficiency as defined in European and international standards (EN 1822 / ISO 29463). In practice, they aren’t vastly different from “True HEPA” but do pinpoint the efficiency level more precisely:

- H13 HEPA: Captures at least 99.95% of 0.3 µm particles (EN 1822 standard) [AIRFILTRATION.MANN-HUMMEL.COM]. In practice, H13 is very close to the U.S. HEPA definition (99.95% vs 99.97%). Many household vacuums with HEPA filters would meet H13.

- H14 HEPA: Captures at least 99.995% of 0.3 µm particles [EMW.DE] [AIRFILTRATION.MANN-HUMMEL.COM]. This is an even higher grade – effectively 10× less leakage than H13. Some commercial or specialty vacuums (and many air purifiers) use H14 filters for extra protection.

- “True HEPA”: This term is commonly used in the U.S. and generally implies the 99.97% @ 0.3 µm standard, which as you can see lies between H13 and H14 in efficiency [WINIXEUROPE.EU]. It’s not a separate class in EN/ISO standards, but manufacturers use “True HEPA” to signify a filter that genuinely meets HEPA requirements (as opposed to “HEPA-type”).

- EPA/ULPA: In the EN/ISO system, filters slightly below HEPA efficiency are labeled EPA (classes E10, E11, E12 for 85%, 95%, 99.5% respectively). Filters above H14 are ULPA (U15, U16, U17), which go all the way to 99.999995% efficiency for extreme applications [EN.WIKIPEDIA.ORG]. ULPA filters are seldom used in regular home vacuums – they’re found in cleanroom environments or specialized industrial vacuums. But it’s good to know the scale: an ULPA U15 filter, for example, must trap at least 99.9995% of the MPPS [EN.WIKIPEDIA.ORG], an efficiency needed for controlling microscopic contaminants.

In summary, any HEPA-class filter (H13 or above, or True HEPA) is highly effective for household needs – they will capture the vast majority of fine dust, allergens, and even many bacteria or virus-laden droplets in the vacuum’s airflow [EN.WIKIPEDIA.ORG]. The differences between an entry HEPA and a top-tier HEPA (H14) are relatively small in practical home use. What’s more important is the overall design of the vacuum that the filter is housed in, which brings us to sealed systems.

Sealed Vacuum Systems: Why Containment Matters

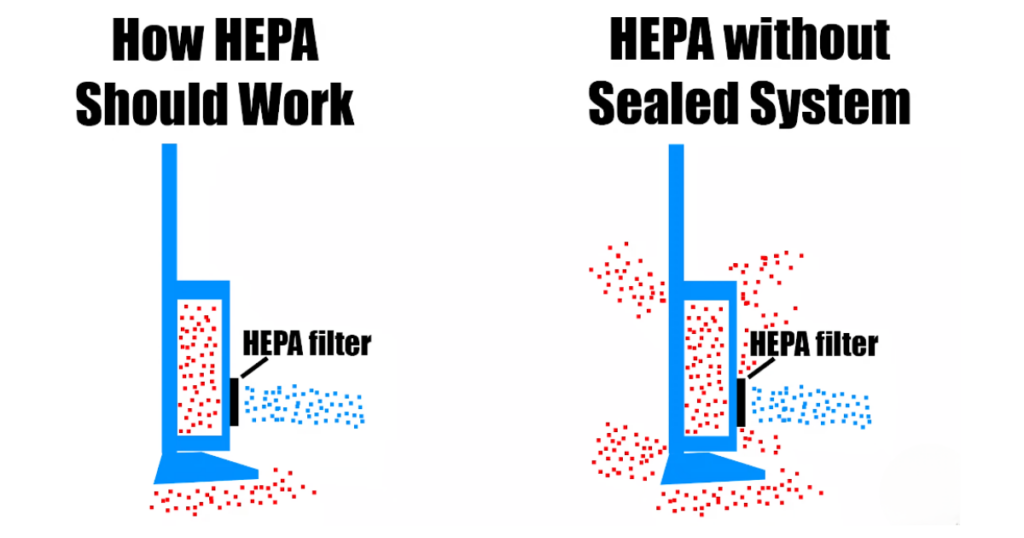

Even the best HEPA filter won’t do much good if the air can bypass it. That’s why a sealed system (sometimes marketed as a “fully sealed” or “anti-allergen” system) is so important. A sealed vacuum system means that all air drawn into the vacuum passes through the intended filters (including the HEPA filter) before being exhausted, with no stray leaks of unfiltered air. Every seam, gasket, and connection in the airflow path is airtight. In an unsealed vacuum, you might have microscopic gaps around the dust bin, hose connections, or filter mount – and under pressure, fine dust can blow out through those gaps back into your home’s air.

The effect of a sealed system is best understood by considering the entire vacuum as one unified filtration system, not just a filter component. Think of the vacuum as a lungs-like system: if there’s a hole in one “lung,” air will escape through that hole rather than going out through the “windpipe” (the filter). High-quality vacuum manufacturers design their machines to prevent such leaks. This often involves rubber gaskets around the filter, tightly fitting dust bin covers, and one-way seals.

In our evaluations and reviews, we’ve observed that only vacuums with sealed systems can truly achieve near-HEPA performance at the exhaust. In fact, U.S. EPA’s definition of a HEPA vacuum for lead dust explicitly includes the requirement that “the vacuum cleaner must be designed so that all the air drawn into the machine is expelled through the HEPA filter with none of the air leaking past it.” [EPA.GOV]. That is essentially the textbook definition of a sealed system.

So How do You Know?

How do you know if a vacuum is sealed? Unfortunately, it’s not always obvious from the specs. Many manufacturers will advertise “sealed HEPA filtration” or use certification logos to indicate it. Third-party programs help here: for instance, the AAFA asthma & allergy friendly certification requires the vacuum’s entire filtration system integrity to be maintained – meaning no appreciable leaks are allowed during operation [ASTHMAANDALLERGYFRIENDLY.COM]. In Europe, during the years of the EU energy label, achieving a top dust re-emission grade (A) essentially meant the vacuum was sealed, because even a small leak would cause more than 0.02% of dust to escape and drop the rating [STORAGE.TOPTEN.EU]. Many brands responded by improving gaskets and seals to meet that standard.

It’s worth noting that bagged vacuums inherently help create a sealed system – the bag itself acts as a sealed container and a primary filter (good bags are made of multi-layer filter material). When you remove a full bag, a well-designed bag seals itself so dust doesn’t puff out. Bagless vacuums rely even more on rubber seals and cyclonic separation before air reaches the filters. Both types can be sealed; it just requires careful engineering.

On the flip side, even a vacuum with a HEPA filter can perform poorly in emissions if it’s not well-sealed. Consumers who prioritize air quality should look for terms like “whole-machine HEPA filtration” or certifications, which imply that the device was tested as a whole unit for leaks. In summary, a sealed system ensures you get the full benefit of the HEPA or high-grade filters inside your vacuum. Without a seal, you might be catching allergens with one hand and spitting them out with the other, so to speak. This is why experts often stress finding a vacuum that is HEPA + sealed, a combination that keeps your indoor air as clean as possible while you vacuum.

(Side note: Even with a sealed HEPA vacuum, it’s wise to open windows or ventilate occasionally when vacuuming, since very fine particles and normal exhaust CO₂ can accumulate. But compared to an unsealed or non-HEPA machine, a sealed HEPA vacuum drastically reduces what’s blown back into your living space.)

When Vacuums and Air Purifiers Overlap

Vacuums and air purifiers are both tasked with removing particulates from air, so it’s not surprising they share technologies – chiefly HEPA filters. A high-end vacuum essentially acts as a mobile air cleaner while it’s running, pulling in dusty air from your floors and expelling filtered air. However, the context and design differ:

Airflow and Purpose

An air purifier continuously circulates room air through a filter to scrub it of dust, pollen, smoke, etc. A vacuum, on the other hand, draws air in primarily to pick up dirt from surfaces; cleaning the air is secondary. Vacuums have much higher airflow when running, but you only run them occasionally. Air purifiers use lower airflow but 24/7 operation. This means an air purifier might remove, say, pollen that’s floating around continuously, whereas a vacuum removes the dust that’s settled into your carpet and in the process also filters some air. There’s an overlap in that both will capture things like dust mite allergens and pet dander – vacuuming removes them from your carpet and an air purifier catches what’s left circulating.

HEPA Filters in Both

The HEPA filters used in vacuums and purifiers are often very similar. In fact, some vacuum cleaner companies also manufacture air purifiers (e.g., Dyson, Miele) and may use similar H13/H14 grade HEPA media across both product lines. One difference is the filter format: vacuum filters are usually smaller, sometimes circular or cartridge-shaped, and designed to fit in a compact appliance, whereas air purifiers often have larger filters to maximize airflow. But both obey the same physics – 0.3 micron particles are the target. You’ll see terms like “True HEPA” in both vacuum and purifier marketing.

An interesting point: “HEPA-type” vs “True HEPA” is an even bigger issue in air purifiers, where some inexpensive purifiers use substandard filters. In vacuums, it’s less common to see “HEPA-type” explicitly; manufacturers either include a real HEPA filter or not. Still, the informed consumer should be on the lookout in both domains.

Standards and Testing

Air purifiers have their own metrics like CADR (Clean Air Delivery Rate) which quantifies how quickly they can remove smoke, dust, pollen from a room’s air. Vacuums don’t have an equivalent public-facing rating for air cleaning, because their primary job is floor cleaning. However, the vacuum industry uses tests like ASTM standards to measure filtration efficiency (for instance, ASTM F1977 measures a vacuum’s particle emissions in lab conditions) [ASTM.ORG]. These are analogous to how an air purifier might be tested for HEPA compliance. Essentially, a vacuum with a sealed HEPA system could perform like a portable air cleaner during use – in fact, one could argue vacuuming with a good vacuum improves your indoor air by removing a lot of dust from circulation. But it’s a short-term, localized effect compared to an air purifier’s continuous cleaning.

To put them in context: if you have allergies or asthma, you’d want to both vacuum with a quality (sealed HEPA) machine and perhaps run an air purifier. The vacuum grabs the allergens from your rugs and floors (where they accumulate), and an air purifier catches those that stay airborne. Both use HEPA tech to make your home’s air healthier. It’s no coincidence that HEPA was first widely used in specialized air filtration (e.g., in hospitals and cleanrooms) and then later became common in home air purifiers and now vacuum cleaners – it’s all part of the same continuum of indoor air quality management.

Conclusion and Future Outlook

From American homes to European apartments to Japanese condos, the trend is clear: better filtration in vacuum cleaners is becoming the norm. Consumers worldwide are more aware of indoor air quality today than ever before. This means higher demand for vacuums that don’t just clean floors, but also help keep the air clean. We’ve seen how the U.S. and Europe took different routes – the U.S. via market innovation and certifications, Europe via regulations – but ultimately arrived at a similar place where a high-efficiency filter and a sealed design are marks of a top-quality vacuum. Other regions are following suit by adopting these technologies and standards.

Implications for Consumers

All this technical detail boils down to practical advice – if you’re shopping for a vacuum and care about filtration (which you likely do if you’ve read this far!), look for keywords like HEPA, True HEPA, sealed system, or specific ratings like H13/H14. Don’t be shy about asking manufacturers for proof or certifications. A reputable manufacturer will often have their vacuum tested to standards (for example, IEC or ASTM filtration tests) and may even publish the results or carry seals from allergy associations.

Also keep in mind that maintaining filtration performance means replacing or cleaning filters as recommended – a clogged HEPA filter can reduce suction and potentially cause bypass leakage [EN.WIKIPEDIA.ORG]. Also, remember that a bagged vacuum can offer a clean way to dispose of dust (no puff of dust when emptying), whereas bagless vacuums avoid ongoing bag costs but require careful emptying to not release dust – in either case, consider how the design handles dust to keep it trapped when you’re done vacuuming [ASTHMAANDALLERGYFRIENDLY.COM].

Implications for Manufacturers

Vacuum makers have the challenge of meeting rising consumer expectations and, potentially, stricter standards in the future. The bar for what’s considered “good filtration” has been raised. We might see a return of regulatory standards – for instance, the European Commission could introduce new eco-design rules focusing on indoor air quality. Manufacturers who invested early in sealed HEPA designs (like some high-end European brands or companies like Dyson, Shark, Miele, etc.) have a competitive edge as these features become mainstream.

However, they also must balance filtration with other factors: powerful suction motors generate more exhaust airflow, which in turn requires very efficient filters and well-sealed systems to avoid emissions. It’s an engineering balancing act between performance, noise, energy use, and filtration. Innovations like self-sealing bags, washable HEPA filters, and even sensor-based filter monitoring (to alert users when it’s time to change the filter) are likely to become more common as manufacturers aim to keep filtration effective without burdening the user with maintenance surprises.

The Future of Filtration Tech

Looking ahead, we can expect vacuum filtration to continue improving. Some emerging trends and possibilities include:

- Better filter media – e.g. nanofiber layers or electrostatic charged fibers that can capture particles with less airflow resistance, meaning you don’t need as powerful a motor to push air through a fine filter. This can allow small cordless vacuums or robots to achieve HEPA-level filtration without killing their battery life.

- UV-C and antimicrobial coatings – a few products have dabbled in adding UV light or anti-microbial treatment to filters to kill bacteria/mold on captured dust, ensuring the filter itself doesn’t become a breeding ground. This is borrowed from air purifiers; it could make its way into vacuums that are stored for long periods with dust inside.

- Sealed docking stations – as robot vacuums with auto-empty bases rise in popularity, we might see the base stations equipped with HEPA filters too (many already have filters). Future designs could include fully sealed dust transfer from robot to base, so even that process doesn’t leak dust (imagine the base sucking debris out of the robot in a closed circuit).

- Convergence of purifier and vacuum – perhaps we’ll see hybrid devices that function as both a floor vacuum and an air purifier when parked on a charging base, pulling double duty. This is speculative, but not too far-fetched as all the core tech pieces exist.

At the end of the day, the goal across all these developments is the same: to keep the air that we breathe in our homes as clean as possible while we clean. A vacuum cleaner shouldn’t be the thing that worsens your air quality – it should improve it, or at least not harm it. With HEPA filters and sealed systems now widely available, consumers no longer have to trade off cleanliness of floors versus cleanliness of air. The worldwide move toward better filtration is a win-win for health. As standards continue to rise and perhaps unify (with ISO standards creating common definitions, and international certifications gaining traction), we may soon reach a point where “poor filtration” in a vacuum is as unacceptable as poor safety or poor suction.

In the meantime, understanding the differences in standards helps buyers make informed choices and encourages manufacturers to keep pushing towards vacuum cleaners that truly leave nothing behind – not on your floors, and not in your lungs.

Frequently Asked Questions

What is a True HEPA filter and how is it different from HEPA-type filters?

Answer: A True HEPA filter meets the official standard of capturing at least 99.97% of particles at 0.3 microns, as defined by the U.S. Department of Energy. In contrast, “HEPA-type” or “HEPA-like” filters are not subject to any regulatory standard and often trap fewer particles—sometimes only 90% or less. Always look for terms like True HEPA, H13, or H14 to ensure high filtration performance.

Why do some vacuums with HEPA filters still release dust into the air?

Answer: Even a high-quality HEPA filter can’t protect indoor air if the vacuum isn’t fully sealed. Without a sealed system, air can leak around the filter or through poorly fitted parts, allowing unfiltered dust to escape. For the best air quality, choose vacuums labeled “sealed HEPA”, “whole-machine HEPA,” or certified by third parties like the Asthma and Allergy Foundation of America (AAFA).

What do H13 and H14 mean on vacuum filters?

Answer: H13 and H14 are European HEPA classes defined under EN 1822 and ISO 29463 standards.

H14 filters capture at least 99.995%.

These designations are often used in premium vacuums and air purifiers, and they offer filtration performance similar to or better than U.S. “True HEPA” standards.

H13 HEPA filters capture at least 99.95% of 0.3-micron particles.

Do vacuum cleaner HEPA standards vary by country?

Answer: Yes, HEPA standards and enforcement vary globally. The U.S. relies on industry terms like “True HEPA” and voluntary certifications. The EU previously had a mandatory dust re-emission rating, encouraging sealed systems, while Japan emphasizes consumer quality and often includes HEPA or even ULPA filters in high-end models. Other countries often follow international standards like ISO 29463 or EN 1822.

How can I tell if a vacuum is actually good for allergies or asthma?

Answer: Look for vacuums that combine a True HEPA filter with a sealed system. Keywords like “sealed HEPA,” “whole-machine filtration,” or AAFA-certified are good indicators. These vacuums ensure allergens like pollen, pet dander, and dust mites are captured and not re-released into your air—critical for allergy and asthma sufferers.